LCD HD44780u

There are many libraries out there that you can find and use them easily without any worry about what happens on the pins of the LCD (Hitachi HD44780). For example, in Arduino you just need to set up some pieces of line code and print string of characters there, really easy and much time save. But for you who want to now a bit more about what data/address is actually accessed to the LCD and how to do it with a microcontroller directly (in this case atemega8535 is used), and (may be) how. this post may help.

There are many libraries out there that you can find and use them easily without any worry about what happens on the pins of the LCD (Hitachi HD44780). For example, in Arduino you just need to set up some pieces of line code and print string of characters there, really easy and much time save. But for you who want to now a bit more about what data/address is actually accessed to the LCD and how to do it with a microcontroller directly (in this case atemega8535 is used), and (may be) how. this post may help.

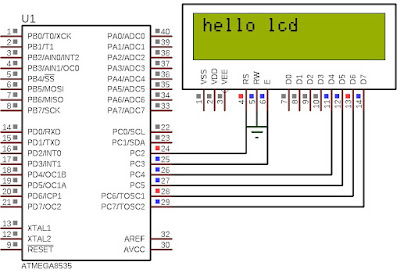

Schematic

Circuit

So

bellow is our schematic circuit diagram

|

| Figure 1 Configuration of atmega8535 and lm016 (proteus) |

Note

that all of our configuration that we are going to discuss bellow is

based on the above schematic. In other words changing any pin or PORT

(e.g., from PORTC like above to PORTB) will make these code useless

(unless you know what should be changed on PORT configuration). The

discussion only emphasizes about memory accessing to the LCD with

atmega8535 MCU without ‘dynamic’ configuration prepared – like

on Arduino.

Files

Needed to prepare

After

the schematic we have, next creating our file hierarchy where we type

our scripts certainly. Bellow they are:

--build

----main.c

----lcd_reg.h

----lcd_reg.c

----Makefile

There

are four files we need to create. For the compiler, I use GNU gcc

compiler of course (and may be always…) with help of Makefile that

I create to compile.

As seen on the above files, there are four of them with a ‘build’

folder where all compiled files are put. I deliberately put the

compiled files (such as .hex, .asm and etc.) separately, so that our

original destination files (the four files) keeps clean. Now just

take a look on the main.c file:

Content of main.c File

#include "lcd_reg.h"

int main()

{

lcd_init();

lcd_print("hello lcd");

while(1);

return 0;

}

From the above lines of code, the purpose may easily be guessed that

the string of “hello lcd” will be sent to the LCD to be displayed

on the its screen. To do that, the first thing we need to do is

‘include’-ing our header file (that we are going to discussed

later). All of parameters and functions prototypes are there in the

header file: lcd_reg.h, that are then to be included in main file,

where our main(){...} definition exists.

In main() function, lcd_init() is called. This is where all LCD

addresses configuration takes place on which our discussion focuses.

The next line is lcd_print() that simply transferring string of

characters to the LCD.

Now lets take a glance on the header file, i.e., lcd_reg.h.

Content of lcd_reg.h File

#ifndef LCD_REG_HEADER_

#define LCD_REG_HEADER_

#include <avr/io.h>

//macros defined

#define DATA_PINS PORTC //port aliase

#define RS 0x04 //pin lcd to mcu

#define EN 0x08

//parameters taken from hd44780u datasheet

//table 6 on page 24

#define FUNCTION_SET 0x20

#define DISP_2LINES 0x08

#define CLEAR_DISPLAY 0x01

#define DISP_CONTROL 0x08

#define DISP_ON 0x04

#define ENTRY_MODESET 0x04

#define ENTRYLEFT 0x02

void send(uint8_t val);

void command(uint8_t val);

void write(uint8_t val);

void enablePin_pulse(void);

void send_4line(uint8_t ch);

void lcd_init(void);

void clear_disp(void);

void lcd_print(const char *s);

#endif

The contents of this file are some macro variables followed by

function prototypes needed by lcd_reg.c file and any other files that

may call it. For the three lines:

#define DATA_PINS PORTC //port aliase

#define RS 0x04 //pin lcd to mcu

#define EN 0x08

is where our pins configuration for the atmega8535 MCU pin/port

register is set. As seen on the schematic figure 1 above that PORTC

is used to interface the LCD. The higher nibble (i.e., PC4, PC5, PC6,

and PC7) of PORTC is used to transfer data-bit into D4, D5, D6, and

D7 respectively. Therefore to ease the semantic of the code,

“DATA_PINS” is used as an alias for PORTC. The next two lines are

RS and EN aliases for PORTC’s pins that we use for the transfer

control. You can see on the figure 1 that PC2 and PC3 are connected

to RS and E of LCD pins respectively. For the hexadecimal values of

0x04 and 0x08, about how to define those values according to the

PORTx of the MCU, you can see it on the related posts bellow.

Posts related:

Note:

The ‘nibble’ term in this case is parts of a byte in data-memory.

Figure 2 bellow depicts what I mean:

Next lines are macro definitions of:

#define FUNCTION_SET 0x20

#define DISP_2LINES 0x08

…

All hexadecimal values of each line of the macros above refer to the

data-sheet of Hitachi HD44780u LCD. These values can be found on page

24 in table 6. These aliases are then passed as argument functions

that call them later.

The lines:

void send(uint8_t val);

void command(uint8_t val);

…

are function prototypes that are also included along with the macros

above. Without these prototypes, main() function cannot call

lcd_init() and lcd_print() functions.

For lcd_reg.c is rather long to attach at once. Therefore each of

function definitions will be explained step-by-step begun from

lcd_init() function.

Content / Definitions of lcd_reg.c File

lcd_init definition

void lcd_init(void)

{

configure_pins();

//since on the schematic, the 4-line connection is used

//we set the lcd mode into 4-bit

//the steps are according to hitachi HD44780 flow-chart, see page 45 - 46

//starting with 8-bit mode

send_4line(0x03);

_delay_us(4100); //wait for 4.1ms

//next step

send_4line(0x03);

_delay_us(4100); //wait for 4100us

//finally

send_4line(0x03);

_delay_us(150);

send_4line(0x02); //for 4-bit mode

//set # lines, font size, etc.

command(FUNCTION_SET | DISP_2LINES);

_delay_us(4200); //waitmore than 4.1ms

//turn the display on

command(DISP_CONTROL | DISP_ON);

//clear the display

clear_disp();

//set the entry mode

command(ENTRY_MODESET | ENTRYLEFT);

}

to ease to explain, we refer to the flow of the function above. Note

that the documentations of the code above may ‘describe’ each

line of the code ‘aim’. And the explanation for next section will

also refer to the documentation.

So the first line of the code calls the configure_pins() function in

which the definition is:

configure_pins Definition

void configure_pins(void)

{

DDRC |= 0xfc; //activate pins according to our schematic

//according to datasheet, we need to wait more than 4.5ms after Vcc rises to 2.7v

_delay_us(50000);

//to begin the command, RW, EN, and RS pins need to be low

//based on our schematic, RW is directly connected to ground

//that automatically has the low state

DATA_PINS &= ~(RS | EN);

}

The definition above aims to activate PORTC on PC2 to PC7, and pull

PC2 and PC3 low for RS and EN pins respectively to start instruction

of the LCD.

send_4line Definition

void send_4line(uint8_t ch)

{

DATA_PINS &= 0x0C; //mask for RS and EN bits

DATA_PINS |= (ch << 4); //shift value according to our schematic

enablePin_pulse();

}

the first two lines of function definition above simply send 4-bit

data via high-nibble of PORTC with 2-bit (for RS an EN pin) data-sate

is retained by masking it with 0x0C. Then the next line

enablePin_pulse() is for pulse generator that is needed by the EN pin

of LCD in each data transferred.

enablePin_pulse Definition

void enablePin_pulse(void)

{

DATA_PINS &= ~EN; //mask by its own value

_delay_us(20);

DATA_PINS |= EN;

_delay_us(20); //enable pulse must be more than 450ns

DATA_PINS &= ~EN;

_delay_us(100); //commands need to be more than 37us

//see table 6 of page 24 for details

}

by referring to its data-sheet that each step in this process needs a

delay at least 450ns. When this process is finished, we need to delay

the execution once more for at least 37us before going to the next

execution / process or before leaving this function.

command Definition

void command(uint8_t val) //command mode

{

DATA_PINS &= ~RS; //rs on lcd pin needs to be low

send(val);

}

by pulling RS line low while transferring any data (by calling

send(val) above), this means that we are transferring in command

mode, otherwise we are transferring in data mode.

send Definition

void send(uint8_t val)

{

send_4line(val >> 4);

send_4line(val);

}

This is where 8-bit data is transferred by way of transferring 4-bit

(or nibble) data twice. On the first send_4line() function, we need

to shift four-bit to the left to get the high nibble of data-bit to

transfer first, and followed by the low nibble of data-bit on the

second call of send_4line(). Note that the HD44780u LCD in 4-bit

mode, the higher nibble of byte needed to be received first, and

followed by the lower nibble.

clear_disp Definition

void clear_disp(void)

{

//clear entire display and set DDRAM to 0 on address counter

command(CLEAR_DISPLAY);

_delay_ms(2);

}

By passing alias value of CLEAR_DISPLAY (or simply 0x02) in command

mode, the display of the LCD and the DDRAM address counter are

cleared and set to 0 respectively. Note that before continuing the

next step, the LCD needs to wait about 2ms for the process to be

done.

lcd_print Definition

void lcd_print(const char *s)

{

while(*s)

write(*s++);

}

This function definition simply prints each character of the string

with write() function. The process is done in while() loop by

incrementing pointer-value / memory-address-value to point to each

character of char array (or simply string).

write Definition

void write(uint8_t val) //write mode

{

DATA_PINS |= RS; //rs on lcd pin needs to be high

send(val);

}

by pulling RS line high while transferring any data (by calling

send(val) above), this means that we are transferring in data mode,

otherwise we are transferring in command mode.

Compiling and Run

Before going to the compiling process, for this project to be able to

run, you need to save all the definition above in a file called

lcd_reg.c. Then just make the file hierarchy like we have already

discussed above with the ‘build’ folder created (the name must be

the same, i.e., ‘build’, because it refers to our Makefile

configuration).

Finally after the hierarchy file you have, like the top of this post,

open your terminal and navigate to this four files destination, and

type

make

then, you would see the message like bellow:

avr-gcc -c -Wall -Os -std=c11 -g -mmcu=atmega8535 -DF_CPU=2000000UL lcd_reg.c -o build/lcd_reg.c.o

avr-gcc -c -Wall -Os -std=c11 -g -mmcu=atmega8535 -DF_CPU=2000000UL main.c -o build/main.c.o

avr-gcc -g -mmcu=atmega8535 -Wl,-Map,main.map -o build/main.c.out build/main.c.o build/lcd_reg.c.o

avr-objdump -h -S build/main.c.out > build/main.lst

avr-size build/main.c.out

text data bss dec hex filename

314 10 0 324 144 build/main.c.out

avr-objcopy -O ihex -R .flash build/main.c.out build/main.c.hex

for the .hex file, you can find it in the build folder.

So here is our Makefile

Makefile Content

MCU=atmega8535

CPU=2000000UL

MCU_FLAG=-g -mmcu=$(MCU)

CPU_FLAG=-DF_CPU=$(CPU)

CC=avr-gcc

main.c.hex : main.c.out

avr-objdump -h -S build/main.c.out > build/main.lst

avr-size build/main.c.out

avr-objcopy -O ihex -R .flash build/main.c.out build/main.c.hex

main.c.out : main.c.o

$(CC) $(MCU_FLAG) -Wl,-Map,main.map -o build/main.c.out build/main.c.o build/lcd_reg.c.o

main.c.o : main.c

$(CC) -c -Wall -Os -std=c11 $(MCU_FLAG) $(CPU_FLAG) lcd_reg.c -o build/lcd_reg.c.o

$(CC) -c -Wall -Os -std=c11 $(MCU_FLAG) $(CPU_FLAG) main.c -o build/main.c.o

For this Makefile, we will discuss on the next post.

That’s it! How we can use the LCD based on address configuration.

Thanks for reading, and if you have any question, just ask bellow on

the comment.

0 Comments

Post a Comment